Electroacoustics (R&D)

IFAA offers engineering services specialized in research and development of electroacoustic systems. We support our clients in development, prototype construction and finalizing CAD data for setting up the serial production.

Starting with the idea, ranging up to the near-series prototype, we can support you.

Design

In the following categories we offer the engineering for complete projects as well as individual services customized to the development of loudspeakers:

- Sound systems

- Horns and waveguides

- Sirens

- Sounder or transducer (piezo and electrodynamic)

- Sample inspection of drivers and loudspeaker chassis

- Crossover design

- Setups for loudspeaker management systems

Sound Systems

Loudspeaker Development

We support your engineering ranging from the definition of new products and sampling of loudspeaker chassis/drivers to the near-series product. For that purpose we use a comprehensive set of specialized tools, including detailed acoustic measurements for testing component samples, 3D CAD modeling of loudspeakers as well as BEM simulation of its directivity including all passive and/or digital crossovers. That way, during the development of a product already, substantial acoustic data can be acquired. Prototypes of horns, waveguides and cabinets can be built in-house virtually on the spot, so that measurements and listening tests can be efficiently performed accompanying, complementing and supporting the designing stage of the product.

Loudspeaker Families and Line Arrays

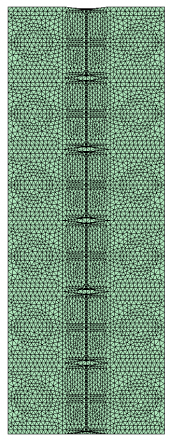

When developing sound systems, it is mandatory to verify not only the acoustic performance of the single cabinet, but also the coupling of loudspeaker groups and the interaction within. Utilizing BEM technique, we simulate loudspeaker clusters and line arrays to test the cluster performance and array coupling with various curvings. This allows us to predict and optimize the acoustic performance of large and complex sound systems without the need for numerous expensive prototypes.

Services

- Definition of products

- Research for suitable chassis and drivers

- Sample inspection of horns, drivers, loudspeaker chassis, damping material, grilles

- CAD development of loudspeaker cabinets

- Development of optimized horns and waveguides

- Simulation of acoustic radiation of complete sound systems including crossover

- Design of passive crossovers and equalizers

- Prototyping from wood and ABS

- Acoustic measurement of prototypes

- Design of setups for loudspeaker management systems (FIR, IIR or FIR+IIR) with optimization of directivity and distortion behavior.

- Design of setup libraries for line array and loudspeaker families

Horns and Waveguides

For the development of horns and waveguides we systematically apply numerical simulation (BEM) and optimization tools. The software we use to generate the geometries and the BEM solver have been developed in-house. To increase simulation accuracy at high frequencies, measured sound waves (3D scanning of the driver’s mouth) can be combined with the BEM calculation.

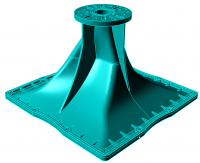

Not until the acoustical performance, e.g. a particular directivity, meets the requirements, an exemplar is produced with ABS prototyping. At this stage already all the future series-production details can be added to the CAD model, like flanges, ribbing, and so on. In addition to the acoustic measurements, this allows realistic mechanical testing of the near-series prototype.

Services

- Development of horns, horn families, waveguides for line arrays, waveguides for dome tweeters and conical diaphragms

- Numerical optimization of horns and waveguides

- Measurement of horn samples and waveguides

- Working out CAD data toward near-series state

- Rapid prototyping

- Acoustical measurements on prototypes

Sirens

We develop sirens for a variety of applications, ranging from tiny piezo driven devices in smoke detectors to high performance alarm sirens for police cars, fire brigade, etc..

We support your development by inspecting samples of transducers and by helping you choose the optimal solution. The development of sound wave guiding geometries is supported by BEM simulation technique, in order to optimize the radiation pattern and the efficiency of the device. Furthermore while developing the design, efficiency measurements are carried out on prototype devices. If required, we also support the serial production with follow-up measurements and by analyzing occurring problems.

Services

- Development

- Sampling of loudspeaker chassis, horn drivers, piezo transducers

- Development of optimized horns and waveguides

- Simulation of acoustical radiation

- Rapid prototyping

- Acoustical measurements on prototypes

- Serial measurements and analysis to support the large-volume production

Sample Inspection of Loudspeaker Chassis and Horn Drivers

During development

The selection of a suitable speaker chassis or horn driver provides the basis for a successful development of a sound system. Apart from its parameters, also the acoustic measurement results of the chassis, like harmonic distortion, maximum SPL, directivity or break-up mode characteristics, have to fulfill the specific requirements. We support our clients by searching suitable components and carry out the laboratory measurements. Our long-time experience with inspecting chassis of all sizes and types lets us help you find the most adequate components.

Qualification of components

To verify quality and endurance of loudspeaker components, stress tests with high and low temperature, salt water etc. can be carried out. When indicated, this is done according to company standards (e.g. automotive or aerospace industry), ISO standards, or others. By comparison of acoustical endurance tests on a component before and after exposure to the stress tests, durability and degradation of the device can be derived. We support you with all acoustical measurements, which are necessary to evaluate the qualification of acoustical components for high demands.

During serial production

In large-volume productions, like of smoke detectors, car alarm systems or similar products, often there is a set of minimum requirements concerning the acoustical characteristics that have to be fulfilled. By performing series measurements under laboratory conditions followed by a statistical analysis of the results, it is possible to derive the rejection rate for the large-volume production.

Services

- Research for loudspeaker chassis, micro loudspeakers, horn-drivers

- Sample inspection of components

- Qualification testing of components according to company standards and ISO standards

- Accompanying measurements during series production

Crossover Design

When developing passive crossover networks for equalizing and filtering the separate channels of a multi-driver loudspeaker, a number of parameters have to be optimized at the same time. Apart from the crossover operation for a desired overall frequency response and the slew rate of the filters, the resulting directivity around the crossover frequency and the respective requirements have to be taken into consideration. Furthermore, the topology of high-power networks for large scale sound systems has to be optimized regarding power dissipation to keep the network devices from heating up. For designing passive networks we use commercial network solvers and optimizers as well as our own software tools, which take into account the influence of the network on the directivity. Especially for designing multi-way systems with overlapping frequency bands, like column speakers, a complete simulation of the system including all crossover functions is an indispensable tool for optimizing the radiation pattern.

Services

- Crossover design with optimization of directivity and network topology

- Prototyping of passive networks

- Measurement and analysis of passive networks

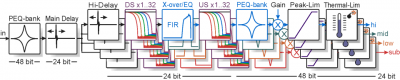

Controller Setups

Setups for loudspeaker management systems

Before building setups for a loudspeaker management systems, we extract as much information from the speaker as possible. Minimum requirement is measuring the transfer functions (magnitude and phase) for each driver in an anechoic room. From these results, we create crossover filters considering magnitude and phase of the speaker. If the loudspeaker management system supports independent adjustment of magnitude and phase, it is possible to have a system with linear phase that is, no phase distortion.

For also optimizing the directivity, we perform balloon measurements and analyze the effect of different crossover filters on the directivity. With our proprietary software tools we determine the resulting transfer function and directivity from the balloon data and the crossover functions. This allows us for instance, to systematically use overlapping bands to optimize the directivity. Furthermore, for specific combinations of amplifier and speaker, the limiter settings are adjusted.

In the end a measurement of the complete system and a listening test for a subjective evaluation is carried out. For multiple speakers/line arrays, we implement the appropriate filters for different combinations.

Cardioid setups for (sub)woofers

In order to create setups for cardioid (sub)woofers, extensive and elaborate free field measurements in wide open spaces (parking lots, soccer fields) need to be carried out. To circumvent excessive costs, we use a process, which combines measurements in an anechoic chamber with BEM simulation technique. At first, laboratory measurements of a single subwoofer with its individual drivers are performed, followed by a BEM simulation of the desired arrangement of multiple subwoofers, which exactly incorporates the geometry of the housing, every single loudspeaker membrane and the occurring diffraction. Appropriately merging measurement and simulation data provides the basis for establishing user-defined setups.

From this data, it is possible to easily create presets for arbitrary numbers and arrangements of subwoofers for any kind of application.

Services

- Measurements of individual speakers in a loudspeaker system

- Design of setups for loudspeaker management systems (FIR, IIR or FIR+IIR) with optimization of directivity and distortion behavior.

- Design of setup libraries for line array and loudspeaker families

- Implementing limiters

- Design of cardioid setups for arbitrary speaker arrangements

- Implementation of setups on arbitrary loudspeaker management systems

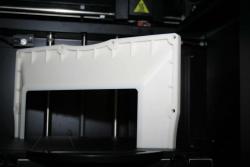

Prototype Construction

In our manufacturing facilities we can produce all the components needed for developing horns, waveguides, loudspeakers or line arrays. This makes possible a straightforward realization directly from the CAD data, in order to perform acoustic measurements, listening tests or mechanical testing. Horns, waveguides, holds or small cabinets are built with our 3D ABS printer. For manufacturing wooden cabinets or front baffles, we usually cooperate with carpenters.

Rapid Prototyping

Horns, waveguides, holds or small cabinets are built with a 3D ABS printer. The process is based on the FDM technology (Fused Deposition Modeling), which constructs a model with layers of a thermoplastic material. The ABS model material we use shows about 70% of the stability of the ABS used for injection molding. This allows us to manufacture even complex near-series prototypes straightforwardly derived from CAD data, and to perform acoustical or mechanical testing. Our 3D printer builds prototypes up to dimensions of 10″x10″x12″. Larger parts can be assembled from several parts, which makes it possible to build even large horns with high precision. After surface finishing, ABS parts can be used to produce molds for setting up a first series production. This allows the immediate start of a preproduction series after verifying the acoustic design.

Services

- Rapid prototyping

Wood Prototyping

We use prototype cabinets made from wood for testing the acoustic behavior during the development. Complex baffles are processed by a CNC milling machine.

Services

- Prototype cabinets

- CNC-milled baffles

CAD Service

In the course of a project, if required, CAD models are worked out in order to prepare the serial production, for instance when using injection molding. We add flanges, ribbing, and other details to the CAD model, depending on the customer’s requirements.

Services

- Working out CAD data of horns, waveguides, etc. for setting up injection molding production or other manufacturing processes